Here are a few adhesive tape types and processes you should know about to make the right choices:

From agriculture to packaging, and consumer items, adhesive solutions have a key role to play in many industries because of their functionality and convenience. For effective decision-making regarding the solution you should choose, it’s essential to understand the basics of what is being offered in the market.

As a responsible supplier of adhesive solutions, Davik continues to guide its customers and support them by helping them understand the available solutions. This is the second article of our series on key characteristics and terminologies of the adhesive packaging that you should know about before proceeding with the process.

7 must-know terminologies related to types of tape adhesive and related solutions

Effective decision-making requires further understanding of the common terms the adhesive industry uses. We believe that the following 7 are among the most important terminologies you must be aware of.

1 – Shear resistance

In the engineering domain, shear strength/resistance is the ability to resist deformation parallel to the surface. It’s the same for all types of tape adhesives as well. The shear resistance of tapes deals with the amount of force required to pull a tape parallel to the surface it’s fixed to.

2 – Adhesion

In the simplest terms, it’s the strength of the bond your tape and adhesive solution delivers. In many cases, the adhesion depends on multiple external factors like the heat, surface, and type of tape. The adhesion strength differs, of course, in different formulations of adhesives. Davik, for example, has developed both low tack and strong bond adhesives for various applications.

3 – Elongation

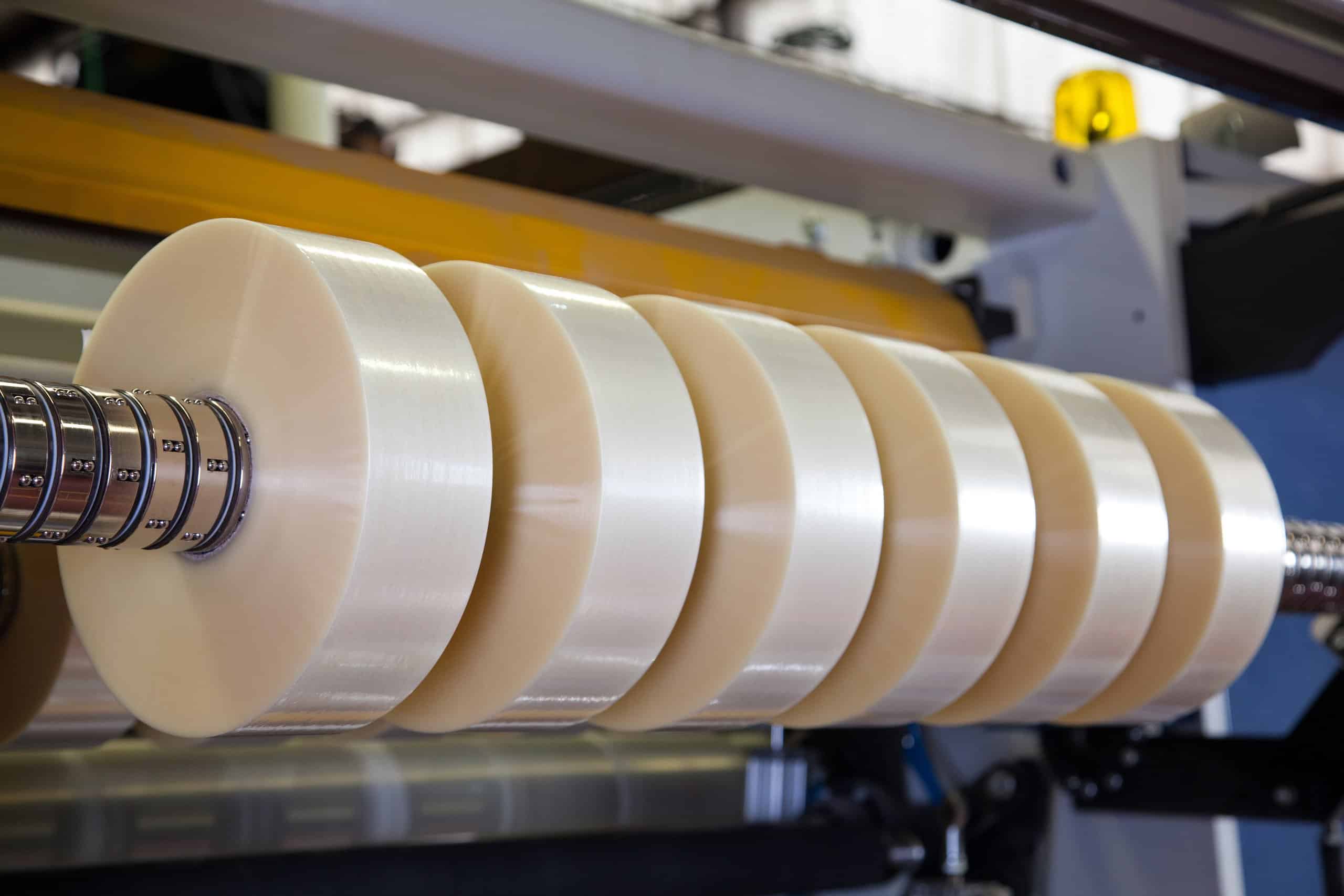

Elasticity and elongation are engineering characteristics that show the strength limit of any tape. The test checks how far your solution will be able to stretch before breaking.

4 – Tack

The ability of the tape to stick quickly. Naturally, tapes with quicker operations are better because you won’t have to wait for a long time. Generally, high tack tapes are for universal situations while the others are for some specialized applications or surfaces.

5 – Peel adhesion

Most tapes we commonly deal with are pressure-sensitive. This means that they don’t need any additional water or anything else for the process. The peel adhesion strength is the force you’ll need to remove an applied tape from a surface.

6 – Natural rubber versus synthetic rubber (hotmelt)

Natural rubber is produced naturally from the native Brazilian plant Hevea brasiliensis. Synthetic rubber is artificially produced from a variety of polymers which provides the rubber its properties. Is synthetic rubber better than natural rubber?

In general, synthetic rubber offers better resistance to abrasion than natural rubber, as well as superior resistance to chemicals, fluids, ozone, electrical heat and the effects of aging.

7 – Solvent

In chemistry terms, a solvent is any substance that can dissolve another one. The packaging industry relies on solvents for many of its essential tapes and other compounds. Davik tries to avoid using solvents thinking about the environment. This is why the Davik acrylic plant is based on water technology instead of solvent.

Davik: The perfect adhesive partner for you

Adhesive solutions have now become a norm in many industries. While making a decision regarding the type of adhesive you should choose, it’s best to make an informed choice by knowing about the basic processes and terminologies of the industry. Types of tape adhesive, adhesion capability, mechanical properties, and other important characteristics determine the application and suitability of any solution you use.

As a global player in the adhesive solutions market, Davik has a unique and streamlined system in place that helps you get the best solutions in the shortest time. From types of tape adhesives to helping your business become greener, Davik’s team of experts can help you throughout the process and assist in turning your vision into reality.

Start experiencing the best from today. Contact Davik now.

Our other articles that you might be interested in:

Adhesive solutions for industrial and packaging applications;

Looking for advanced adhesive solutions? Davik is the place to go