In a rapidly changing world where sustainability, cost-efficiency and brand experience matter more than ever, product managers are under pressure to rethink packaging strategies. If you’re responsible for packaging decisions globally, then the evolution of smart adhesive packaging offers an exciting opportunity: to move away from traditional plastic-based wraps and tapes toward paper-based, high-performance alternatives. The transition is not simply a change of material, it is a bold strategic shift that supports business goals, environmental commitment and consumer appeal.

Why Packaging Is No Longer Just a Box

Packaging used to be a silent cost of doing business. Today, it plays a starring role in brand perception, customer convenience, regulatory compliance and sustainability credentials. According to industry-insights from Davik Tape, packaging must serve three core objectives: marketing and user convenience, cost control, and sustainability.

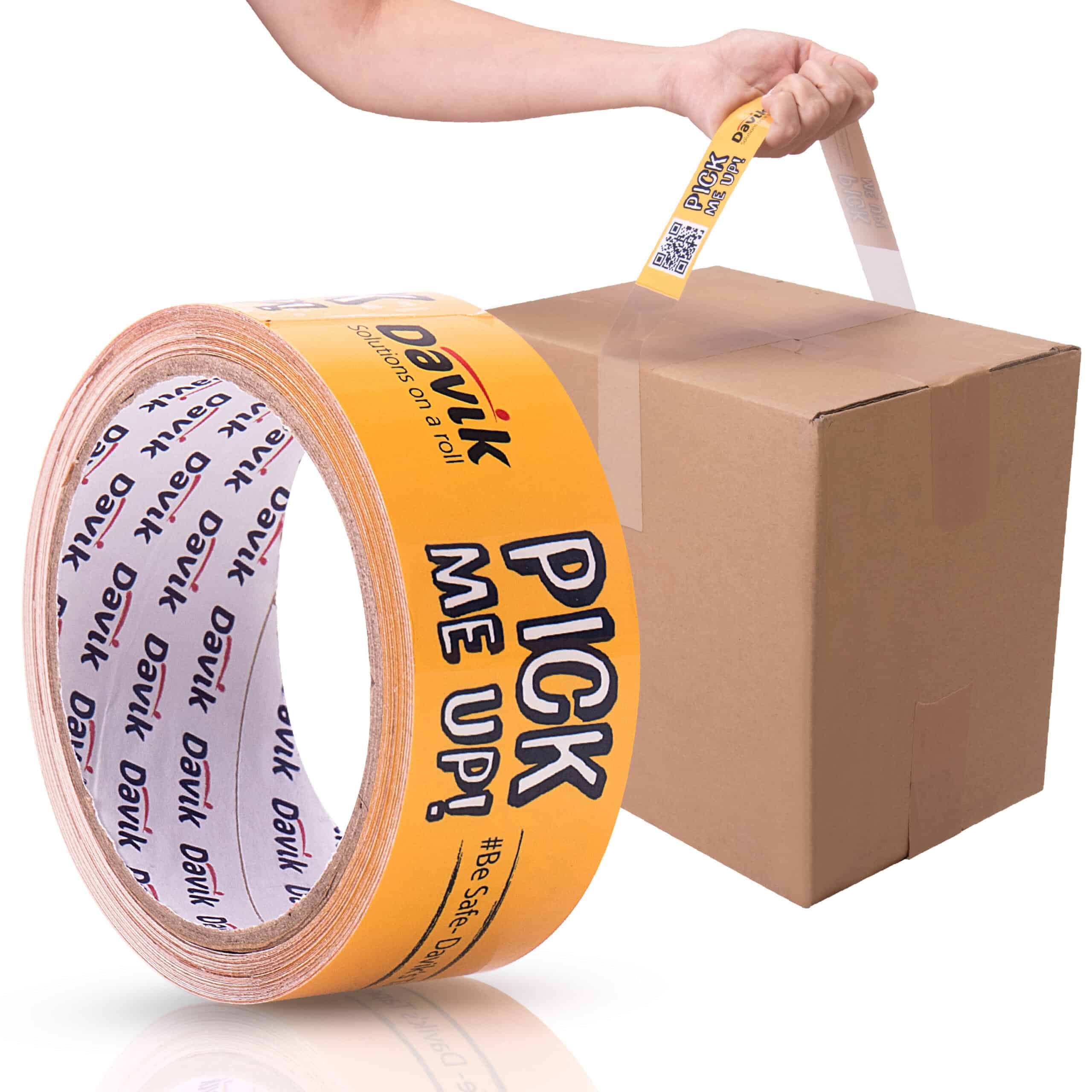

That’s where smart adhesive packaging comes into play. Beyond simply sealing or holding a product, the right adhesive tape or handle solution can enhance the unboxing experience, reinforce brand messaging, simplify logistics and reduce environmental impact. It ties together form, function and commerce.

What Is Smart Adhesive Packaging?

Smart adhesive packaging refers to packaging systems that integrate advanced tape or adhesive components, engineered not just for sticking two surfaces together, but for adding value: ease of handling, brand design, sustainability and smarter logistics. Such solutions go beyond traditional plastic film and hot-melt tapes to materials built from paper, recycled PET (rPET), and other engineered substrates.

For example, Davik’s paper-based carry handle tape and rPET handle solutions demonstrate how adhesive innovations are reshaping packaging. In essence, smart adhesive packaging is an adhesive ecosystem enabling packaging to do more: enable reuse, reduce carbon footprint, impress consumers and perform at production scale.

From Plastic to Paper: A Strategic Shift

Environmental Imperative

The packaging world is under increasing scrutiny. Consumers, regulators and supply-chain partners expect brands to reduce single-use plastic, lower carbon emissions and engage circular-economy principles. Davik notes that their eco-friendly adhesive products allow brands to “meet the packaging needs of today while safeguarding the environment for tomorrow.”

Shifting from plastic-based tapes to paper-based or recycled PET alternatives is a key part of this. For example, paper carry-handle tapes allow brands to eliminate plastic bags and heavy plastic wraps, while paper-based sealing tapes enable easier recycling and lower overall environmental impact.

Business Benefits

Beyond environmental benefits, this shift delivers business advantage. Smart adhesive packaging helps product managers meet cost pressures (by reducing material use or eliminating secondary packaging), improve logistics (lighter materials, easier handling) and elevate brand experience (premium look and eco-messaging). Davik’s case studies show how adhesive carry handles reduce packaging costs and present a marketing surface at the same time.

Brand & Consumer Experience

In a global market where brands compete for attention, packaging becomes a stage for storytelling. Smart adhesive packaging offers new design opportunities: a branded tape handle, printed paper-based seal, custom colours, or user-friendly resealable closures. These aspects strengthen brand-touchpoints, improve consumer convenience and encourage repeat purchase.

How Smart Adhesive Packaging Works in Practice (for Product Managers)

When you consider adopting smart adhesive packaging in your global product line, here are key elements to assess:

- Material compatibility: Paper-based tapes, rPET, and other recycled substrates need to bond reliably to packaging materials (carton, film, board). Ensure your adhesive partner has proven formulations for each substrate.

- Production integration: The chosen solution must integrate into your existing production and packaging line or allow for scalable retrofit. Will this require manual application initially? Automated? Are the new materials compatible with your current equipment?

- Performance requirements: The tape or adhesive must meet strength, durability, environmental (humidity, temperature) and logistics demands. For example, heavy-pack carry handles must support product weight without failure.

- Marketing & brand design: Use the adhesive component as part of your brand narrative. A paper-based handle printed with your logo can convey eco-commitment and attention to detail.

- Sustainability metrics & certification: Verify the films and adhesives support your sustainability goals: e.g., recyclability, low-carbon production, circular-economy credentials. Davik emphasises strong R&D and sustainable solutions as part of their offering.

Two Key Advancements in Smart Adhesive Packaging

Here are two leading innovations you should be aware of:

- Paper-Based Carry Handle Tapes

These replace plastic-film handles or plastic bags. Brands can apply a paper handle directly onto a carton or paper-wrapped pack, improving consumer convenience and removing plastic waste from the equation. Davik highlights paper carry-handles as part of their eco-friendly push. - Paper or rPET Sealing Tapes

Traditional plastic sealing tapes are now being replaced by paper-based sealing tapes or rPET film tapes that are recyclable or made from recycled content. For example, Eco Kraft Tape made from kraft paper, and Reinforced Paper Packing Tape for heavier applications. Our Kraft and paper based tapes can also be printable or printed for the need of your brand awareness.

These advancements illustrate how adhesive-based innovations are pivoting packaging design from plastic-centric to material-neutral, high-performance alternatives.

Why Product Managers Should Act Now

From a strategic standpoint, adopting smart adhesive packaging now gives you a competitive edge. Global regulatory pressure on single-use plastic is growing. Consumer expectations for sustainable packaging are mounting. Meanwhile, early adopters who invest in smart adhesive packaging stand to benefit from cost savings, improved brand positioning and logistics advantages.

If your packaging is still heavily reliant on plastic film, low-value tape solutions or outdated secondary packaging, you risk lagging behind rather than leading. Consider packaging not just as containment but as experience, efficiency and brand statement. Smart adhesive packaging becomes a lever to pull. This is a new era and everyone should adapt!

Implementation Tips for Global Roll-out

- Start with a pilot: Choose a single SKU or region to test the new smart adhesive packaging.

- Work with your adhesive-tape partner early: Collaboration is key to integrate new substrates and adhesives into your line. Davik emphasises that their in-house R&D works through a six-step process to ensure custom solutions.

- Monitor key performance indicators: material cost, handling efficiency, consumer feedback, waste reduction, brand uplift.

- Include packaging marketing messaging: Use labels or printed adhesive tapes to tell your story of sustainable innovation and convenience.

- Scale globally: After successful pilots, roll-out to other markets, adjusting for regional materials, supply-chain and regulatory nuances.

FAQ

Q1: What exactly is “smart adhesive packaging” and how does it differ from standard packaging solutions?

Smart adhesive packaging refers to packaging systems that integrate advanced adhesive components, such as paper-based sealing packaging tapes, carry-handle tapes, or customized adhesive solutions, that go beyond the basic function of containment. Unlike standard packaging which may rely on plastic wrap, generic tapes or film-based solutions, smart adhesive packaging uses engineered adhesives and substrates to add value: improved user convenience, brand messaging, cost efficiency and sustainability. It represents a shift from simply hiding a product in a box, to designing the package as a functional and strategic asset.

Q2: Why should product managers consider replacing plastic tape with paper-based or recycled adhesive solutions?

Product managers should consider this replacement for multiple reasons. First, sustainability is no longer optional: consumers, retailers and regulators expect eco-friendly packaging. Paper-based or recycled adhesive solutions reduce plastic usage and support circular economy goals. Second, cost savings may be realised through lighter materials, simpler logistics or reduction in secondary packaging. Third, brand value increases: using innovative tape or handle solutions tells a story of quality, innovation and responsibility. As the packaging experts at Davik point out, their eco-friendly adhesive products “combine innovation with environmental responsibility.”

Q3: How do smart adhesive packaging solutions impact brand experience and consumer perception?

Smart adhesive packaging influences consumer perception in several ways. When a consumer picks up a product that includes a convenient carry handle, or notices a tape printed with the brand message, it communicates that the brand has paid attention to ease-of-use and design. It elevates the packaging from mere protection to part of the brand narrative. Moreover, when materials are recyclable or clearly eco-conscious, the brand signals alignment with consumer values. Packaging becomes part of the marketing footprint, not just an afterthought.

Q4: What challenges should be addressed when implementing smart adhesive packaging worldwide?

Product managers considering a global roll-out should be prepared for several challenges: compatibility of new substrates and adhesives with existing production equipment; ensuring that the adhesive bonds reliably across different packaging materials and geographies; managing cost impacts and transitions from existing plastics; aligning the supply chain for paper-based or recycled materials; verifying recyclability and local regulatory compliance in each market; and communicating the change to consumers and stakeholders. Working with an adhesive-solution partner who understands these factors, such as the R&D-driven approach of Davik, is vital.

Q5: How can the use of smart adhesive packaging contribute to cost savings and operational efficiency?

Smart adhesive packaging can contribute to cost savings and efficiency in several ways. By switching to lighter or thinner materials (e.g., paper-based tapes instead of thick plastic film) your logistics weight and volume may reduce. A well-designed carry handle tape can remove the need for extra packaging layers or plastic bags, streamlining assembly and reducing material use. According to industry insight, adhesive carry handles “reduce packaging costs and improve functionality” in bulk packaging scenarios.

Also, because some solutions are designed for ease of application (even manual initially) they can speed up production change-over and reduce labour overhead.

Q6: What trends in the global packaging market support the shift toward smart adhesive packaging?

The global packaging market is trending strongly toward sustainability, circularity, and material innovation. Brands are increasingly measured on their environmental impact, with packaging being a critical lever. One industry article by Davik emphasises that sustainability is “a driving force shaping the future of packaging solutions.

Additionally, growth in e-commerce and global logistics demands more efficient, lightweight, and consumer-friendly packaging. Smart adhesive packaging aligns with those demands by enabling easier handling, better brand differentiation and lowered environmental impact.

In conclusion, for product managers overseeing global packaging, embracing smart adhesive packaging is more than a material swap, it is a strategic investment. Moving from plastic-centric solutions toward paper-based, recycled and engineered adhesive systems positions your brand for the future: environmentally credible, user-centric and operationally efficient. The new chapter in packaging is being written, and it begins with the tape, the handle.

the seal and with your decision to lead rather than follow.