As supply chains recalibrate and consumer expectations continue to evolve, 2026 presents a unique inflection point for packaging decision-makers. The choices made at the beginning of this year will ripple through operations, brand perception, and customer satisfaction for months to come.

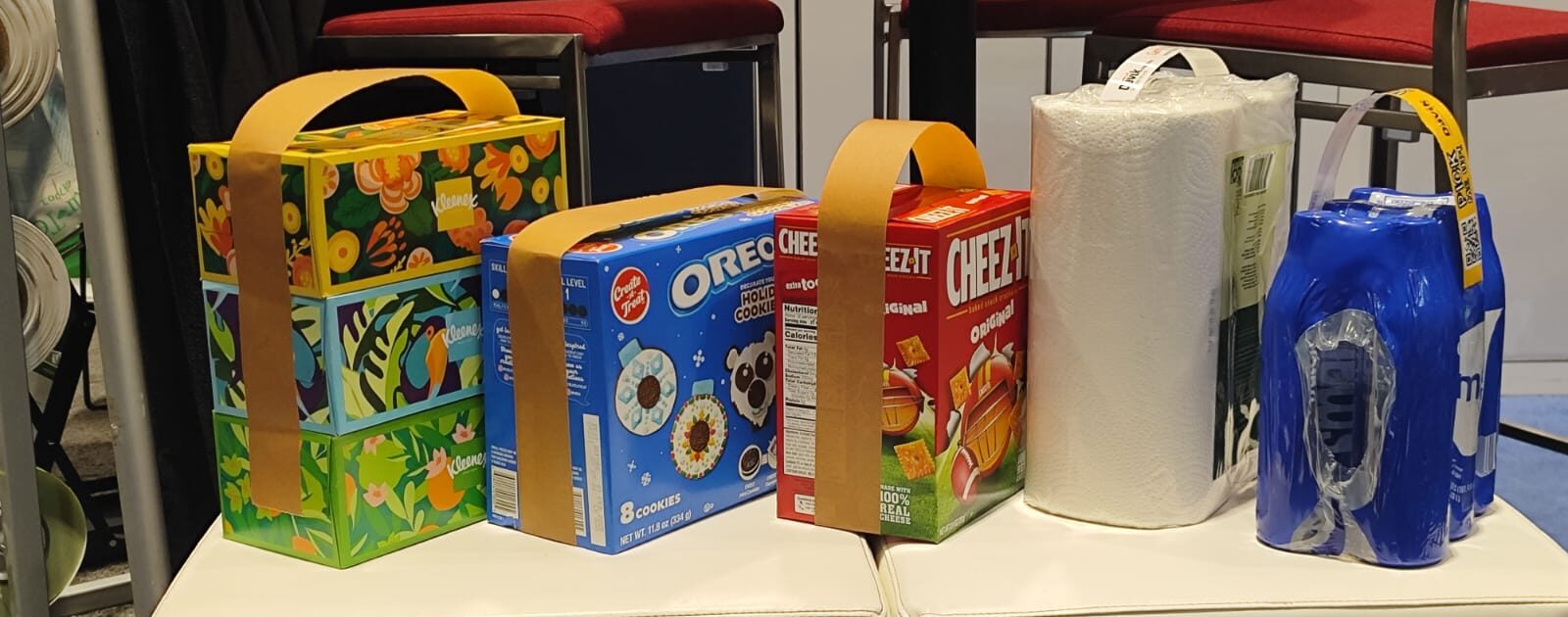

For companies managing high-volume products—from beverage multipacks to household essentials—one often-overlooked element holds surprising power: the carry handle.

What began as a simple convenience feature has matured into a strategic packaging component that influences production efficiency, sustainability metrics, brand visibility, and the physical experience consumers have with products. The carry handle sits at the intersection of operational performance and human-centered design, making it an ideal starting point for packaging optimization in 2026.

This article examines how thoughtful carry handle selection can create measurable improvements across multiple dimensions: streamlining production workflows, enhancing on-pack branding opportunities, reducing material waste, and delivering the kind of intuitive, comfortable carrying experience that builds quiet brand loyalty.

Rethinking Efficiency: Production Integration as a Strategic Priority

Most packaging conversations focus on primary materials or visual appeal, treating handles as commodity afterthoughts. This perspective leaves significant value on the table.

Production inefficiencies often stem from handle application challenges, while poorly designed handles create consumer friction that shapes purchasing decisions at an unconscious level.

Production efficiency in 2026 demands more than faster line speeds. It requires packaging components that integrate seamlessly with existing equipment while maintaining flexibility for future needs. Modern carry handle solutions offer application versatility that aligns with diverse production environments.

- Handles delivered on rolls can feed directly into automated applicators, eliminating manual handling and associated labor costs.

- Pre-laminated versions reduce process steps, speeding throughput while maintaining consistent quality.

- Handles that perform reliably in both manual and automated environments provide operational flexibility.

Adhesive technology has advanced significantly, with formulations now tailored to specific packaging materials and application methods. Using the right adhesive reduces failures, minimizes waste, and ensures consistent performance across production runs.

Changeover time is another overlooked efficiency factor. Carry handles supplied in consistent formats with clear application parameters reduce setup complexity and keep lines running productively.

The efficiency gains extend beyond the packaging facility. Handles that maintain reliable adhesion throughout distribution reduce failures in transit and at retail, protecting product integrity and brand reputation.

Branding Real Estate: Transforming Handles into Marketing Assets

In competitive retail environments, every square centimeter of packaging surface represents an opportunity to communicate brand values. The carry handle—prominently positioned during lifting—offers prime branding real estate.

Printable carry handles transform a functional component into a marketing tool. Logos, sustainability claims, seasonal graphics, or promotional messages can be incorporated directly into the handle without changing primary packaging.

Color customization further enhances brand alignment, shelf differentiation, and perceived product value. A well-designed handle communicates quality, care, and brand attention to detail.

Material Matters: Navigating the Sustainability–Performance Balance

Sustainability is now a central purchasing criterion. Carry handle materials span a spectrum of environmental profiles:

- Paper-based handles: renewable, recyclable, and ideal for sustainability-forward brands.

- Recycled PET (rPET): durable, moisture-resistant, and containing high post-consumer recycled content.

- Recyclable PE solutions: compatible with shrink film recycling streams.

True sustainability balances material choice with performance. A handle that fails undermines both product integrity and environmental credibility.

The Ergonomics of Everyday Interactions

The physical experience of lifting and carrying products creates emotional impressions that influence repeat purchase behavior.

- Handle placement affects balance and strain.

- Width determines pressure distribution across the hand.

- Material softness influences grip comfort.

Inclusive design matters. Handles that work for seniors, children, and individuals with reduced grip strength expand usability and demonstrate brand empathy.

Smart Implementation: A Framework for Handle Selection

- Production Environment Assessment – automation level, throughput, equipment compatibility.

- Material Compatibility Analysis – surface type, adhesive requirements.

- Performance Requirements – load, transport distance, environmental exposure.

- Sustainability Alignment – regulatory needs, corporate goals.

- Brand Integration – color, print, messaging opportunities.

- Consumer Testing – comfort, perception, ease of use.

Why 2026 Is the Moment for Handle Optimization

Regulatory pressure, rising consumer expectations, supply-chain resilience needs, and labor constraints converge to make 2026 a decisive year for packaging improvement.

Making the Change: Practical Implementation Steps

- Phase 1 – Assessment (Weeks 1–4)

- Phase 2 – Testing (Weeks 5–12)

- Phase 3 – Implementation (Weeks 13–20)

- Phase 4 – Expansion (Week 21+)

Conclusion

Carry handles represent a rare opportunity: low implementation risk, fast impact, and alignment with sustainability, efficiency, and consumer experience priorities.

Seemingly small details increasingly determine competitive advantage. In 2026, the carry handle is no longer a detail—it is a strategic lever.

FAQ

1. Why should packaging handles be reviewed in 2026?

Because regulatory pressure, sustainability targets, labor costs, and consumer expectations converge this year, making handle optimization a fast, visible win.

2. How do carry handles impact production efficiency?

Through automation compatibility, adhesive reliability, reduced changeover time, and fewer failures during distribution.

3. What sustainable options exist for carry handles?

Paper-based, rPET, recyclable PE, and material-efficient designs—all offering different performance and environmental trade-offs.

4. How can handles support branding?

Via printing, color customization, sustainability messaging, QR codes, and premium material feel.

5. Why does ergonomics matter?

Comfort directly influences perception, loyalty, and willingness to repurchase—especially for frequently bought products.

6. How should companies implement changes?

With a phased, test-driven approach supported by experienced suppliers and cross-functional alignment.